Product Quality

This section summarizes the common characteristics and quality standards for ceramic products.

Additionally, ceramics vary in characteristics depending on the clay and glaze used.

For this reason, please check the series your product belongs to.

About Celadon

Each Celadon piece shows a wide range of color variation, so the shade you receive may differ slightly from the photos provided. We hope you’ll enjoy these natural differences as part of the beauty and individuality of handmade ceramics.

About Natural

The Natural color may show a soft pinkish hue known as Gohon-te, a natural kiln effect that occurs during firing. This gentle variation is part of its charm and will not change color over time, so you can use it with confidence.

About Reddish Black

Due to differences in firing conditions, the color of Reddish Black pieces may vary slightly from one to another. We hope you’ll appreciate these variations as part of the natural character of pottery.

Reddish Black pieces feature a distinctive brushed texture with a slightly rough surface. You may feel gentle unevenness or grain when holding them, please enjoy this tactile quality as part of their authentic ceramic appeal.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards.

Burn Marks

At times, you may find burn marks on the surface of our pottery. These are natural kiln variations, known as yōhen, that occur during firing. They are part of the ceramic’s unique character and do not affect its use or quality.

Pinholes

When bisque-fired, air trapped in the clay body or organic matter (such as dust) may remain as tiny holes after firing. These small holes are called pinholes. A visual specialty of pottery, these do not effect the quality of the product, and there is no need for further concern when used.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards.

We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Glaze Drips

Some glazes are designed to flow easily in the heat of the kiln, creating gentle drips or patterns as they move downward during firing. These natural variations are part of the beauty of ceramic expression.

Wobble

HIJICA plates are characterized by their gentle, organic shapes. Please enjoy the slight variations that make each piece unique.

Color Variation

Each HIJICA piece shows its own gentle range of color variation, so the item you receive may differ slightly from the photos. We hope you’ll enjoy these natural differences as part of the beauty and individuality of handmade ceramics.

The “White” pieces are unglazed, allowing the natural tone of the clay to speak for itself. Depending on the firing, soft irregular patterns may appear on the surface. These are harmless and part of the organic character that makes each piece unique.

Wobble

Hitotsuki plates and bowls are characterized by their gentle, organic shapes. Please enjoy the slight variations that make each piece unique.

Gohon-te

Due to a natural kiln variation called Gohon-te, the Moon White glaze may appear with a faint pink tone. This is a natural result of firing and does not indicate discoloration or quality issues.

Pattern

The appearance of the pattern may vary depending on how the glaze has flowed or how the pattern was imprinted. Each piece carries its own subtle expression, shaped naturally through the making process.

Burn Marks

At times, you may find burn marks on the surface of our pottery. These are natural kiln variations, known as yōhen, that occur during firing. They are part of the ceramic’s unique character and do not affect its use or quality.

Individual Variation

Each piece is carefully handcrafted, so its facial expression and body shape may differ slightly from the photos shown. We hope you’ll enjoy these subtle differences as part of its individual charm.

Color Variation

The color of each piece may differ slightly from the photos. Further, because of differences on clay and firing per batch, differences in color and finishes may occur. We hope you’ll enjoy these natural variations as a reflection of the beauty and individuality of handmade ceramics.

Pinholes

When bisque-fired, air trapped in the clay body or organic matter (such as dust) may remain as tiny holes after firing. These small holes are called pinholes. A visual specialty of pottery, these do not effect the quality of the product, and there is no need for further concern when used.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards. We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Burn Marks

At times, you may find burn marks on the surface of our pottery. These are natural kiln variations, known as yōhen, that occur during firing. They are part of the ceramic’s unique character and do not affect its use or quality.

Burn Marks

At times, you may find burn marks on the surface of our pottery. These are natural kiln variations, known as yōhen, that occur during firing.

They are part of the ceramic’s unique character and do not affect its use or quality.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface.

Each piece has been carefully inspected and meets our quality standards. We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Lines on surface of plates

GRAIN WARE pieces are intentionally left with a natural finish to bring out the pure character of the clay. Fine lines or slight marks may appear, reflecting the material’s honest texture.

Color Variations

The color of each piece may differ slightly from the photos.

Further, because of differences on clay and firing per batch, differences in color and finishes may occur. We hope you’ll enjoy these natural variations as a reflection of the beauty and individuality of handmade ceramics.

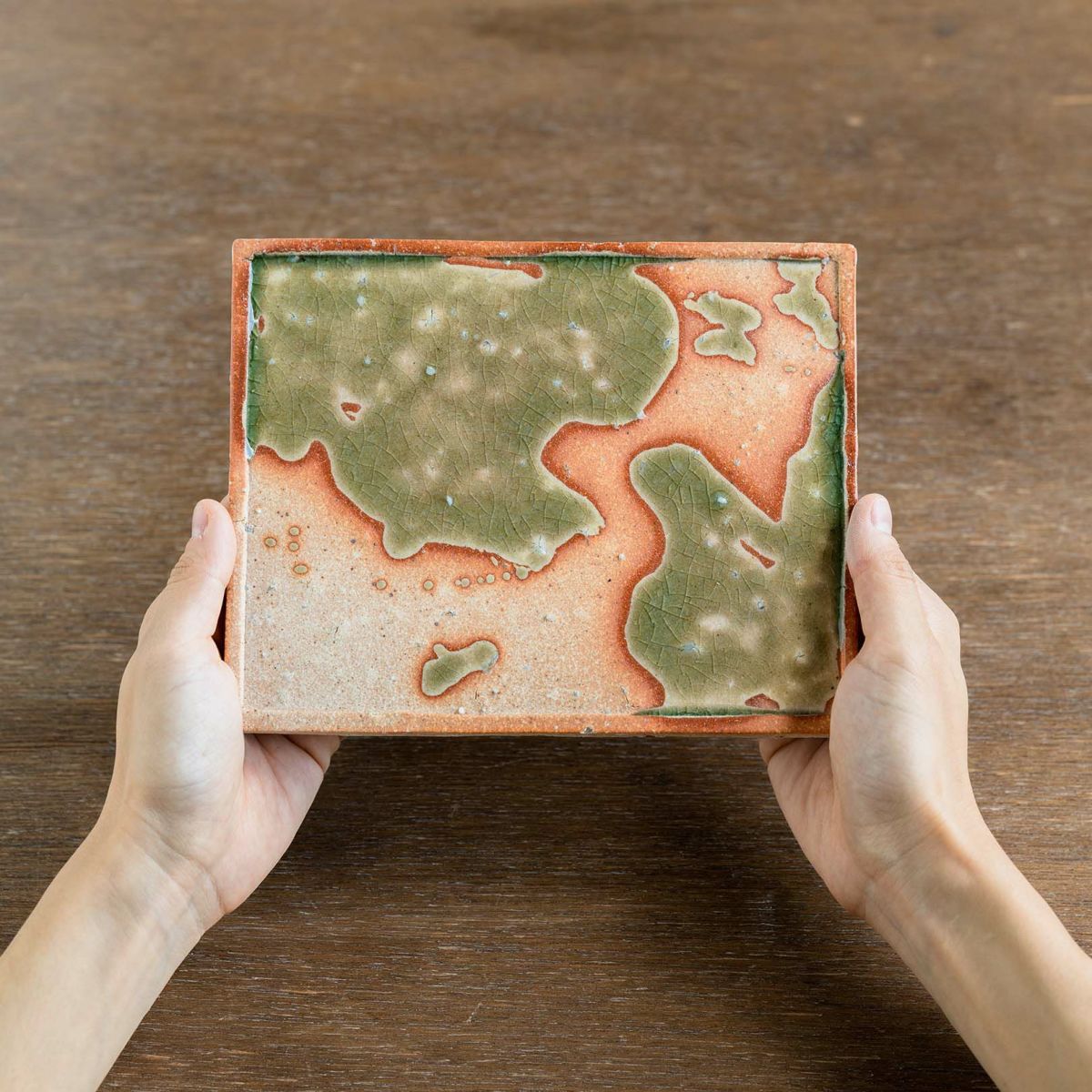

Stone Burst

Stone Burst refers to small spots where feldspar contained in the clay bursts during firing and becomes visible on the surface. If you notice tiny areas along the rim that look slightly chipped, these are places where small stones have burst and disappeared in the heat of the kiln. These natural marks are a characteristic feature of pottery and do not affect its use or quality.

Feldspar Particles

Shigaraki clay contains a high amount of feldspar. When the kiln temperature reaches around 1250–1280°C, the feldspar melts and forms small, white, glassy specks on the surface of the clay. These specks are affectionately called “kani-no-me”—literally “crab’s eyes”—for their delicate, dotted appearance. They are a natural feature of Shigaraki ware, reflecting the character of the clay and the heat of the kiln.

Kannyū

Kannyū refers to the fine crackle pattern that appears when the pottery cools after firing. It forms naturally as the clay body and glaze contract at different rates. If you listen closely beside a cooling piece, you may even hear a gentle “ping... ping...”—the sound of the kannyū forming. These delicate lines are a quiet mark of the ceramic’s life and a cherished feature of traditional pottery.

Color Variation

Koshigaraki pieces use a traditional glaze made from natural materials, giving them a wide and organic range of colors. Through yōhen—the transformation that occurs in the kiln’s flame—layers of color overlap to create subtle, one-of-a-kind patterns and a deeply expressive surface. Each piece reflects the quiet beauty born from clay and fire.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards. We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Enjoy with Appreciation

Every mark and texture in pottery has its own story. Each expression is there for a reason—born from the materials, the hands that shaped it, and the fire that completed it. We believe that imagining how a piece was made while using it brings a deeper sense of connection and warmth to your daily life.

Pinholes

When bisque-fired, air trapped in the clay body or organic matter (such as dust) may remain as tiny holes after firing. These small holes are called pinholes.

A visual specialty of pottery, these do not effect the quality of the product, and there is no need for further concern when used.

Stone Burst

Stone Burst refers to small spots where feldspar contained in the clay bursts during firing and becomes visible on the surface. If you notice tiny areas along the rim that look slightly chipped, these are places where small stones have burst and disappeared in the heat of the kiln.

These natural marks are a characteristic feature of pottery and do not affect its use or quality.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards.

We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Color Variation

The color of each piece may differ slightly from the photos. Further, because of differences on clay and firing per batch, differences in color and finishes may occur.

We hope you’ll enjoy these natural variations as a reflection of the beauty and individuality of handmade ceramics.

Pinholes

When bisque-fired, air trapped in the clay body or organic matter (such as dust) may remain as tiny holes after firing. These small holes are called pinholes. A visual specialty of pottery, these do not effect the quality of the product, and there is no need for further concern when used.

Glaze Drips

Some glazes are designed to flow easily in the heat of the kiln, creating gentle drips or patterns as they move downward during firing. These natural variations are part of the beauty of ceramic expression.

Product Body

A visible line may appear near the center due to the manufacturing process.

This is not a defect and does not affect product quality. Please use the item with confidence as part of its natural characteristics.

White Spots

Some pickling jars may have small white spots inside or on the bottom.

These are glaze patterns formed naturally during firing and do not affect quality or usability.

Color Variation

The color of each piece may differ slightly from the photos. Further, because of differences on clay and firing per batch, differences in color and finishes may occur. We hope you’ll enjoy these natural variations as a reflection of the beauty and individuality of handmade ceramics.

Kiln Variation

Because each piece is fired under slightly different conditions, the glaze surface may show individual variations. This is called yōhen, a natural transformation that occurs during the firing process and is characteristic of ceramics. It does not affect use or quality.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards. We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Color Variation

The color of each piece may differ slightly from the photos. Further, because of differences in clay, glaze and firing per batch, differences in color and finishes may occur.

We hope you’ll enjoy these natural variations as a reflection of the beauty and individuality of handmade ceramics.

Kiln Variation

Because each piece is fired under slightly different conditions, the glaze surface may show individual variations.

This is called yōhen, a natural transformation that occurs during the firing process and is characteristic of ceramics. It does not affect use or quality.

Iron Inclusions

Clay used for pottery contains various natural elements such as iron and microorganisms. During firing, these components may appear as small black spots on the surface. Each piece has been carefully inspected and meets our quality standards.

We hope you will appreciate these marks as part of the natural character and charm of ceramic ware.

Stone Burst

Stone Burst refers to small spots where feldspar contained in the clay bursts during firing and becomes visible on the surface.

If you notice tiny areas along the rim that look slightly chipped, these are places where small stones have burst and disappeared in the heat of the kiln. These natural marks are a characteristic feature of pottery and do not affect its use or quality.

Feldspar Particles

Shigaraki clay contains a high amount of feldspar. When the kiln temperature reaches around 1250–1280°C, the feldspar melts and forms small, white, glassy specks on the surface of the clay.

These specks are affectionately called “kani-no-me”—literally “crab’s eyes”—for their delicate, dotted appearance. They are a natural feature of Shigaraki ware, reflecting the character of the clay and the heat of the kiln.

Cracks

As the clay gently shrinks during firing and drying, fine cracks may form on the surface or between pieces. We check to ensure all pieces are properly attached and these cracks are only surface-level.

Individual Variation

Each piece is carefully handcrafted, so its facial expression and body shape may differ slightly from the photos shown. We hope you’ll enjoy these subtle differences as part of its individual charm.

Cracks

As the clay gently shrinks during firing and drying, fine cracks may form on the surface or between pieces. We check to ensure all pieces are properly attached and these cracks are only surface-level.

Burn Marks

At times, you may find burn marks on the surface of our pottery. These are natural kiln variations, known as yōhen, that occur during firing. They are part of the ceramic’s unique character and do not affect its use or quality.

Brush Streaks

The white mini trees and snowmen are finished with soft, hand-brushed textures. Subtle brush marks may be visible, adding to their handcrafted charm.